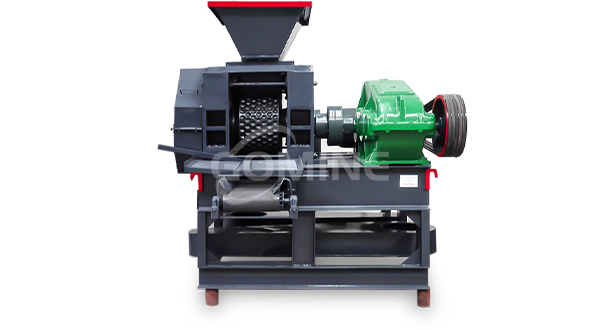

The briquette making machine is mainly used for pressing powdery materials that are difficult to form. It is mainly used in the following industries:

1. Coal industry, blast furnace fuel industry, and power plant: coal, charcoal, coke and other solid fuels briquettes;

2. Steel making plant and metallurgical industry: metal powder like iron ore powder, copper ore powder, etc.

3. Metal waste recycling industry: solid waste like iron oxide, steel slag, etc.

4. Charcoal briquettes production in barbecue and home heating.

Briquette production line

The briquette press machine is the core equipment of the briquetting making plant, and the supporting equipment includes hammer crusher, binder mixer, vertical dryer, biaxial mixer, feeder, mesh belt dryer, etc. According to the needs of customers, we will configure different solutions. Below is the layout of 1t/h charcoal briquette production line.

Briquette making machines for different materials:

Coal Briquette Machine

When we mine the coal, transport it, dry it, there comes a lot of coal dust. As matter of fact, about 20% of the coal we can get is in small particles. So, coal briquette is a good way to deal with these fine or dust as briquette has more burning value and utilization rate.

Charcoal Briquette Machine

Charcoal briquette is a very good fuel compare to biomass briquette which is also widely used. When we turn the biomass into charcoal, after a series of pyrolysis reactions, we remove the smoke, smell and only leave the carbon with the raw material, this makes the charcoal briquette with the advantage of smokeless, odorless and high burning value (80% ahead of biomass briquette) when burnt.

Mineral Briquette Machine

Directly use mineral dust will make lots of waste of the raw material as well as the energy cost, thus briquette them and use the briquette in furnace become a good way to solve the problem.

Common minerals: Iron ore powder, Manganese Ore, Chromium ore, Silica, Bauxite, Fluorite, Magnesite, Dolomite, Limestone, Quicklime, Bentonite, Copper ore, etc.

Lime Briquette Machine

The ball press compresses the lime powder into a briquettes, which can replace the lime block as a good desulfurizer in the converter steelmaking. At the same time, in the production of calcium carbide, the lime briquettes can also replace the lime block to smelt the calcium carbide. The ball press machine improves the utilization rate of waste materials and has good economic and social benefits.

Gypsum Briquette Machine

Desulfurization gypsum has another name as FGD gypsum, most of which comes from the power station as a byproduct. These desulfurization gypsums, with powdery status, is hard for transportation and storage. Dust pollution is also caused by it. Making briquette from this raw material will help to solve these problems.

Technical parameter of briquette making machine:

| Model | Roller Diameter (mm) | Capacity (t/h) | Power (kw) | Reducer |

| GM-290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| GM-360 | 360 | 3-5 | 7.5-11 | 350 |

| GM-430 | 430 | 5-8 | 15 | 500 |

| GM-500 | 500 | 8-11 | 30 | 650 |

| GM-650 | 650 | 10-15 | 37-45 | 750 |

| GM-750 | 750 | 20-25 | 45 | 750 |

| GM-850 | 850 | 20-28 | 55 | 850 |

| GM-1000 | 1000 | 23-35 | 90 | 1000 |

Briquette making machine accessories

The roller of our ball press machine is made of wear-resistant alloy, and the bearing adopts the rolling mill bearing series, which is quenched and tempered, which effectively improves the service life of the machine.

We are experts in the field of solid waste recycling especially metal recycling. We can provide a complete set of solutions, including waste cable recycling, waste circuit board recycling, metal and non-metal crushing and sorting, mixed plastic recycling, etc. If you have any need of our machine, feel free to contact Gomine Machinery.